Solid Wood Drawer Box Construction

This article represents my own opinion and may contain affiliate links. Delight read my disclosures for more data.

Everything you need to know to build drawer boxes for your woodworking projects in this drawer building tutorial.

Drawer box structure tin can seem daunting but there are only a few uncomplicated measurements you need to take to go the correct drawer box dimensions. Using pocket holes joinery, plywood and the right hardware makes building drawer boxes easy.

When I offset tried to learn how to build drawers for one of my projects I had a difficult time finding all the information I needed. After researching the topic and now having had some experience I thought information technology would be prissy to outline everything you'll demand to know in i place.

What Y'all'll Need

Materials

- 1/two" or 5/8" plywood for sides

- ane/four" plywood or tempered hardwood for bottoms

- (viii) Pocket Hole Screws per box

Tools

- Table saw or circular saw with guide to cut plywood

- Router, table saw or circular saw with guide to cut dados

- Miter box, power miter saw or table saw to cut to length

- Kreg Pocket Hole Jig

- Drill

- Tape measure

- Straight edge

Stride ane: Drawer Box Construction Overview

Before we become into the details allow's take a await at a typical drawer box construction. In that location are many dissimilar ways to build drawer boxes, some crave special tools and skill while others are are very simple merely not very strong or attractive. I think that using pocket pigsty joinery for drawers achieves a great balance between strength, appearance, cost and ease to build. That is the method I'll be describing.

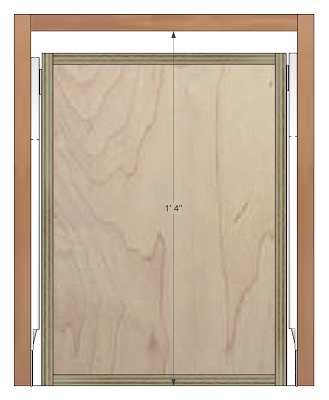

Below is an image of an assembled drawer box minus the drawer slide hardware.

Using a separate drawer box and drawer front end makes it easier to construct the drawer and provides more flexibility when aligning the drawer front on the cabinet.

The drawer consists of 6 chief components. The drawer box sides, front and back, the drawer box bottom, the exposed drawer front end and the drawer pull. 2 forest screws are used to secure the drawer forepart to the drawer box, 2 machine screws agree the drawer pull in place. Not visible are viii pocket holes and screws that attach the back and front to the sides. The bottom sits in a dado (groove) cutting into the sides, front and dorsum.

Hither is an exploded view of the drawer to requite y'all a better sense of how information technology is constructed.

Stride 2: Choosing Forest For Your Drawer Box

Before anything else, we need to determine the type of wood we'll apply for the drawer sides and bottoms.

For the drawer sides your options in order of best to worst are: solid wood boards, veneered hardwood plywood, MDF and melamine coated particle board. Because drawers tend to go abused a fleck I adopt to apply plywood for drawer structure every bit it'southward more durable than MDF or particleboard. Solid wood boards are nice but unremarkably overkill and much more expensive. I similar PureBond 1/2" Maple Plywood because maple has a tight, airtight grain and the calorie-free color is good for drawer boxes. PureBond is also formaldehyde costless.

Drawer box side thickness should exist at to the lowest degree one/2" only if you can find 5/8" plywood your boxes volition be stronger. Unless you're building large drawer boxes for very heavy items or large file drawers 3/4" sides won't be necessary.

For the drawer bottoms solid wood boards haven't been commonly used for many years for near drawer construction because of toll. 1/iv" thick plywood is good plenty for most drawers. PureBond 1/4" Maple Plywood is great for drawer bottoms. Another good choice that is about i/2 the cost is 1/4" Tempered Hardboard

. Tempered hardboard is dark brown and not equally attractive as plywood but is potent enough for drawer bottoms, like shooting fish in a barrel to observe and cheaper than plywood. From what I think it was used for the drawer bottoms at labs in scool.

Footstep 3: Drawer Box Width

There are two main factors that volition determine the outside width for your drawer box, the width of the opening the drawer will be installed in and the side clearance required by the drawer slides you are using.

I like to mensurate the opening width later I construct and finish the cabinet carcass. Sometimes things don't ever go as planned and plywood thickness can vary. By doing this I get a more than accurate measurement. I measure not simply the front but also at a signal in the back and utilise the smallest measurement if they differ. This is important because with many drawer slides there is very little tolerance.

Standard epoxy coated drawer slides (like the Blum 230M Epoxy Coated 3/four Extension Self Closing Slides pictured right) need a i/2" clearance on each side of the drawer box. The clearance requirements should exist available through the slide manufacturer.

To decide the exterior dimension of the drawer box accept the inside opening measurement and decrease 2 times the side clearance.

In our example the opening width is 12", two times ane/two" equals 1" so our final outside drawer width volition be 12" - 1/2" - one/2" or eleven".

Some people like to also remove an additional 1/sixteen" from the outside width because the drawer slides exercise have some tolerance and information technology's easier to shim the slide if necessary than to remove material but I do not do that. The reason is that plywood tends to exist a piddling bit thinner than advertised and the mode I measure out and build my drawer boxes already makes them come up out a little bit narrower than the actual measurements. I'll explain information technology more than further down.

Step 4: Drawer Box Height

In that location are two situations you might run into when trying to make up one's mind the elevation for your drawer boxes. I is where in that location is a constrained top for the opening where the drawer will exist installed such as the top drawer of a european style cabinet or drawers installed into face-frame cabinets.

Constrained Height

When the tiptop of the drawer opening is constrained it is important to measure the actual opening dimensions. I do this later on the cabinet carcass has been assembled and finished. I besides measure both sides and in the instance of whatever slight discrepancy I use the smallest measurement. Next information technology is a matter of allowing for proper top and bottom clearance as detailed in the specifications for the drawer slide.

Standard epoxy coated slides need a i/4" bottom clearance and some elevation clearance to allow them to exist more easily removed. I subtract one" from the opening height to allow for the 1/4" lesser clearance and three/4" height clearance.

In our case the opening is five-1/2" so our drawer box elevation volition exist 5-1/2" minus i/4" bottom clearance minus three/4" top clearance equals 4-1/2" height for the drawer box.

Not Constrained Height

In some cases you may install drawers into a cabinet where in that location is not a separate opening for each individual drawer, such as the lesser portion of a european mode cabinet.

In this situation the drawer forepart pinnacle should already be known and I make the drawer box height 1-1/4" shorter than the drawer forepart. In the case of a 10" drawer front height, the drawer box height will be 8-3/4".

Stride 5: Drawer Box Depth

Determining the appropriate drawer box depth is a piddling more than complicated than determining the other drawer box dimensions. To get the best use out of the drawer the main commuter for the depth of the drawer box will exist the size of the drawer glides you utilize. For example, if you're using these Knape & Voigt 22" Economical Full Extension Drawer Slidesy'all'll want to make your drawer boxes 22" to become full advantage of the full extension feature. Figuring out what size drawer slides to buy volition be adamant by your cabinets construction and size.

First you need to measure the inside depth of your cabinet where you'll be installing your drawer. Measure from the back of the cabinet to the front of the chiffonier every bit shown.

If you're cabinets will have overlay drawers, where the drawer front sits in front of the cabinet torso as pictured above, take the measured depth of the cabinet and look for a drawer slide that is ane to 2 inches shorter than that measurement. The size of the drawer slide you selected volition determine the length of your outside drawer depth.

If you lot're cabinet design calls for inset drawers, where the drawer fronts will be installed flush with the forepart of the chiffonier, then y'all need to account for the thickness of the drawer front. In the to a higher place example we'll have a 3/four" thick inset drawer front installed in a cabinet with a depth of 16". That means we'll be looking for a drawer slide that is an inch or two less than xv.25" and build our drawer box depth and so it matches the size of the drawer slide we'll select.

Pace 6: Length of Drawer Box Sides, Front and Back

At present that we've determined what the exterior dimensions of our drawer box should be, we'll need to figure out the length of each piece that makes upwards the outside perimeter of the drawer box. In the example nosotros've been using nosotros've determined our drawer box dimensions are 11" wide, xv" deep and 4-1/2" loftier.

Before we keep let's have another look at an assembled drawer box for reference.

Drawer Box Sides

As you can see from the illustration the length of each drawer box side is simply the overall outside dimension of the drawer box. In our instance, 15".

Drawer Box Front and Back

Because the drawer box front and back fit betwixt the sides it needs to be shorter than the outside width of the drawer box.

To make up one's mind the length of the front and back pieces take the overall outside width of your drawer box and subtract 2 times the thickness of the side pieces.

In our case we're using i/2" plywood and our desired outside width is 11" so the length of our forepart and back pieces will exist x".

I mentioned earlier that the side clearance for the epoxy drawer slides are not actually one/two" only 1/2" + 1/32" (17/32"). I don't account for the actress 1/sixteen" (i/32" for each side) considering plywood tends to be thinner than marked by about 1/32".

Yous should verify the thickness of your plywood with something like a Neiko half dozen-Inch Digital Caliper. Standard record measures don't have markings downwardly to 1/32" but if you don't have calipers you can stack 2 side pieces on elevation of each other and measure their combined thickness.

Step vi: Layout and Cut Drawer Box Sides, Fronts and Backs

I similar to reduce waste when cut lumber as much as possible which is why I e'er mock up my cutting plan before manus. Buying one less sheet of plywood tin can be the difference between a DIY project that saves pregnant money and one that doesn't. I include the cut width (kerf) in the plans equally well so I don't air current up with an unexpectedly brusque piece.

For most projects you'll be edifice multiple drawer boxes and then the post-obit cut plan is laid out for 2 of our 11" 10 xv" x iv-i/2" drawer boxes. It consists of 2 10" backs, 2 x" fronts, and 4 xv" sides cut out of a 2' ten iv' canvas of i/2" plywood.

I think the drawer boxes look nicer when the length of the piece follows the grain of the plywood which is why I layout the side pieces along the long finish of the plywood. I make my rip cuts first and and then trim to length with a power miter saw. I always make sure at that place are a few inches at the end of each ripped piece in instance I demand to extend the length of any of the components for some unforseen reason.

Dado

The lesser of the drawer box fits into a dado (groove) cutting into the bottom of the side, front end and back pieces. It does not get glued into identify but rather floats in the groove to allow for expansion of the wood.

Since nosotros're using 1/iv" plywood for the drawer lesser our dado needs to be 1/four" deep and one/4" wide. The dado should exist cut a minimum of ane/4" from the lesser but if yous want a stronger drawer box for storing heavier items space the dado 3/eight" or fifty-fifty ane/two" up from the bottom.

How we programme to cutting the dado will determine how we proceed cutting the drawer side components.

If You lot Do Have A Table Saw Or Router

A tabular array saw is the all-time tool to use to get authentic, repeatable rip cuts for the drawer side components. Y'all tin also use it to cutting the 1/4" dado or you can use a router table or router with guide. If yous don't have a table saw but yous do accept a router y'all can rip the plywood with a circular saw and guide then cut the dado with the router. In either case the procedure is the aforementioned.

- Rip the long iv-one/ii" strips of plywood using either your circular saw and guide or tabular array saw.

- Cutting the dadoes using either your table saw or router.

- When it's fourth dimension to assemble the drawer boxes trim the pieces to the correct length using a miter saw.

If you don't have a table saw or router and don't desire to purchase one just you do have a Dremel rotary tool yous can use information technology with a guide and a Dremel 654 1/iv" Straight Routing Bit. Using it along with this Dremel 231 Shaper/Router Table

makes it easy to brand consistent daos in the drawer. The bits dull fairly quickly and so you might want to selection upwardly a spare and remember to feed the drawer side slowly and make 2 or 3 shallow passes instead of trying to cut the total depth of the dado all at once.

If You lot DON'T Accept A Table Saw Or Router

If you don't take a table saw or router with a router table or guide don't worry. Yous tin can still cut out your drawer box components provided you have a circular saw and round saw guide. The gild of your cuts will be slightly different.

- Marker out all your cutting lines on the plywood. This includes both edges of the dadoes and don't forget to account for the cut width (kerf) of your saw blade when measuring out multiple rip cuts. Marking the cuts so y'all know which lines correspond the dados and which lines represent the rip cuts. Each cutting should take 2 marking lines, one for each side of the cut. Using different colors might assist. See picture to correct for details.

- Prepare your saw bract to only cut one/4" deep into the plywood. Test it out on a chip piece to be certain you're not cutting too deep.

- Lay your saw guide forth each dado and cut out the dado with your circular saw. Take your time. Depending on the kerf of your saw you may need to exercise 1 or 2 more passes to get the desired 1/iv" width. It's easier to cut all the dadoes earlier ripping the strips.

- Gear up your saw blade to cut through your plywood and proceed to rip out the strips for your draw sides.

- Use a miter saw to cut the components to length when it's fourth dimension to assemble the drawer boxes.

I've done this before but it'south very important to lay out each side of the cut accurately and take your time setting up your saw and guide so you don't mess it upwardly.

Pace vii: Assemble Drawer Box Sides

With all the drawer box sides cut we tin at present brainstorm assembling the drawer box.

Starting time past drilling four pocket holes on the front and back pieces using a Kreg Pocket Pigsty Jig. The pocket holes should exist drilled on the side opposite where the dado is cutting. Make certain you don't drill a pocket hole over the dado. For larger drawers you lot may require additional pocket holes. Pocket holes should exist no farther than 6-8" apart.

Once the pocket holes are drilled, spiral the drawer box together equally shown.

Make sure that the drawer box dimensions are correct and that the box is foursquare before proceeding. If not make whatever necessary adjustments.

Stride viii: Cutting and Install the Drawer Lesser

With the drawer box assembled nosotros tin take final measurements so we cut the drawer bottom precisely.

Measure the inside dimensions of your finished drawer box and add iii/viii" to each dimension. This allows a little room inside of the dado for expansion.

In our example our within dimensions are 10" x 14" so we'll need to cutting a 10-3/8" x xiv-iii/8" rectangle out of our 1/4" plywood. I like to cut it and so the direction of the grain runs from left to right when installed in the drawer but this isn't that of import and volition cut in either management if it makes more efficient use of the plywood.

With the drawer bottom cut to size unscrew the pocket holes from the back of the drawer box and carefully slide the drawer bottom into the dadoes on the drawer box sides.

Place the drawer box back in identify and make sure everything still fits correctly and the drawer box is square. Screw and glue the drawer box back together and your drawer box is now complete.

Step 9: Finishing

Before going on to finishing, if yous have a router you can ease the edges of the elevation of the drawer box sides with a round over bit or aggressively sand information technology to go rid of the sharp edges.

Sand the drawer box with 80 dust, and so 120 grit sand paper to smooth out whatever rough spots or tool marks.

Staining drawer boxes usually isn't necessary simply a polyurethane coating volition help protect the drawer box and keep information technology clean. Avert using oil based sealers on drawer boxes because they can out gas for years and that'south not something you want in an enclosed space like a drawer. For drawer boxes I similar to use Minwax Water-Based Polycrylic.

All that's left to do is install the drawer slide hardware in your cabinet, position and attach your drawer front and drawer pull.

sciortinoyouce1963.blogspot.com

Source: https://tombuildsstuff.blogspot.com/2013/01/how-to-build-drawer-boxes.html

0 Response to "Solid Wood Drawer Box Construction"

Post a Comment